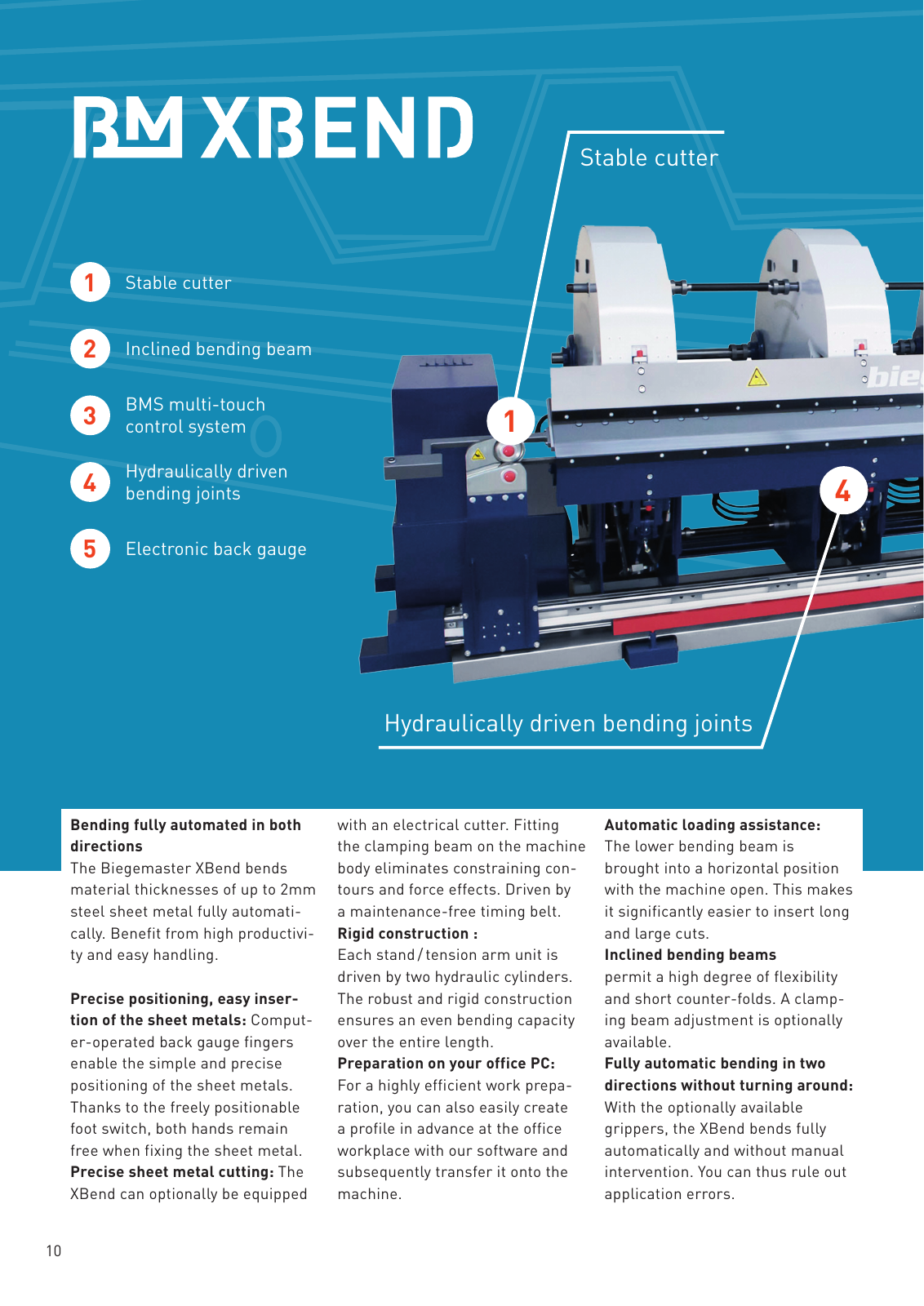

10 Bending fully automated in both directions The Biegemaster XBend bends material thicknesses of up to 2mm steel sheet metal fully automati cally Benefit from high productivi ty and easy handling Precise positioning easy inser tion of the sheet metals Comput er operated back gauge fingers enable the simple and precise positioning of the sheet metals Thanks to the freely positionable foot switch both hands remain free when fixing the sheet metal Precise sheet metal cutting The XBend can optionally be equipped with an electrical cutter Fitting the clamping beam on the machine body eliminates constraining con tours and force effects Driven by a maintenance free timing belt Rigid construction Each stand tension arm unit is driven by two hydraulic cylinders The robust and rigid construction ensures an even bending capacity over the entire length Preparation on your office PC For a highly efficient work prepa ration you can also easily create a profile in advance at the office workplace with our software and subsequently transfer it onto the machine Automatic loading assistance The lower bending beam is brought into a horizontal position with the machine open This makes it significantly easier to insert long and large cuts Inclined bending beams permit a high degree of flexibility and short counter folds A clamp ing beam adjustment is optionally available Fully automatic bending in two directions without turning around With the optionally available grippers the XBend bends fully automatically and without manual intervention You can thus rule out application errors Stable cutter Hydraulically driven bending joints 1 4 Stable cutter BMS multi touch control system Hydraulically driven bending joints Electronic back gauge Inclined bending beam 1 2 3 4 5

Hinweis: Dies ist eine maschinenlesbare No-Flash Ansicht.

Klicken Sie hier um zur Online-Version zu gelangen.

Klicken Sie hier um zur Online-Version zu gelangen.